Engineering and Licensing

The hydroprocessing technology is licensed through development of a basic engineering design package (Sch A package). The process design starts in our pilot plants where we run the clients actual feeds to determine the reactor design. The design feed as well as off design feeds are run through our pilot plants which result a plant design with maximum flexibility.

Basic Engineering Design

Duke Technologies provides the basic engineering package for each project. This package typically includes the following deliverables:

• Design Basis: Feed stock compositions are listed for the design case and off design cases as well. Battery limits conditions, product specifications, and utility availability are defined.

• Process Description: The purpose and characteristics of process unit operations and equipment are outlined in narrative form.

• Equipment List: A list is provided to identify all required process equipment.

• Process Flow Diagrams and Heat & Material Balances: Process simulations for the plant are developed. All process streams are defined in tabular and flow sheet format. Temperatures, pressures, flow rates, and physical properties are defined for all process streams.

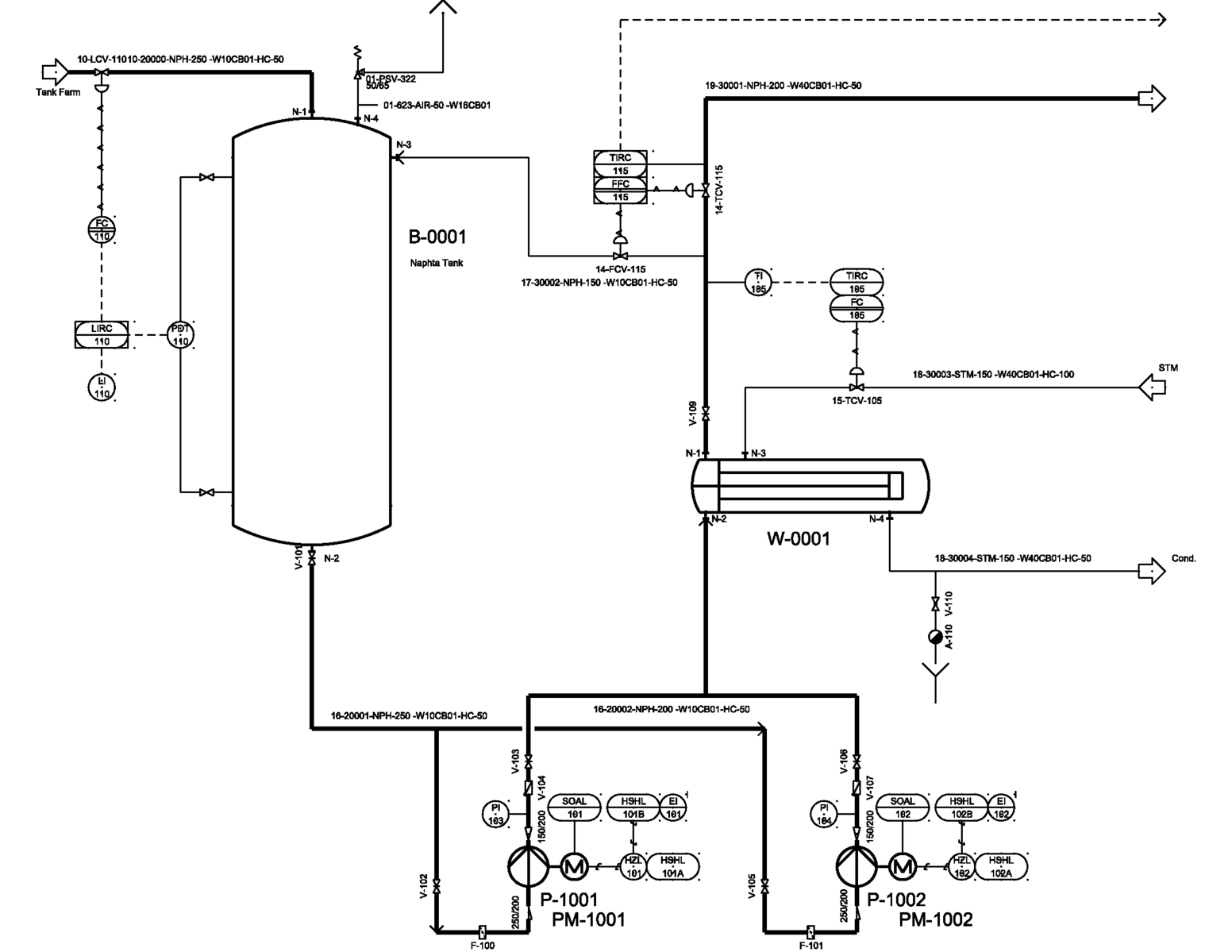

• Piping and Instrumentation Diagrams: Diagrams are provided to show the interconnection of process equipment and the instrumentation used to control the process. Interconnection of key process utilities (hydrogen, steam, hot oil, etc.) is identified

• Process Equipment Data Sheets: Process data sheets are provided for all Inside Battery Limit (ISBL) equipment items.

• Instrument List: Control valves, level instruments, flow instruments, pressure instruments, temperature instruments and relief devices are specified.

• Piping: A piping specification and metallurgy diagram are typically provided.

• Utilities Consumption: Required utilities are identified and consumption rates are shown.

• Summary of Plant Products: A summary of all of the plant products is included.

• Catalysts and Chemicals: A listing of the required catalysts and chemicals is included.

• Line List: A listing of all the major process lines with their operating and design conditions is provided.

• Relief Load Summary: A summary of the different plant relief scenarios is provided.

• Suggested Plot Plan: A suggested overall plot plan is included.

Startup and Operations

Duke Technologies, as part of a comprehensive program, provides training and operating manuals for Duke Technologies designed hydroprocessing units. The operating manuals include standard operating procedures for operating the plant as well as plant startup, shutdown and troubleshooting problems that may occur. Engineer and operator training is done at the project site. The training familiarizes the plant personnel with the process, equipment, instrumentation, and covers other material in the operating manuals. The training program is a valuable resource for a successful and reliable operation.

Home

Home